Metal spinning Metal spinning is made of a disk or cylinder of sheet metal that's placed onto a mandrel over a lathe along with a roller Device designs the sheet to your mandrel condition.

Community keep rates may differ from those exhibited. Items shown as readily available are Usually stocked but stock amounts can not be assured.

Why we like them: Lots of the much less expensive sets we analyzed for our cotton sheets tutorial felt scratchy or low-cost, but not the Threshold Overall performance 400 Thread Depend Sheet Set. The brink Efficiency sheets aren’t really as great as our favorite percale and sateen sets, but inside our assessments they carried out better than sets 4 moments the cost.

Holes having a diameter fewer than the thickness can result in deformation or could possibly be inaccurate mainly because of the kerf or distortion caused by the laser beam.

If the opening is positioned to close towards the bend, the hole might turn out to be distorted or could act as an unintended relief cut.

When you have completed your design and style and prepared your file, add it to our fast quotation Device and get your tailor made bent sheet metal job commenced!

Brass and Bronze: These copper alloys possess an attractive aesthetic look and retain exceptional corrosion read resistance, creating them perfect for attractive components.

Regardless of whether you might be looking for solutions to marketplace difficulties or All set to speculate in efficient machinery, MachineMFG has what you may need. Explore how we can help you succeed.

Buy it on line or at any Metal Supermarkets place, cut for your actual technical specs. Select from one of many offered metal types below to start. Or Make contact with your closest retailer for guidance with metal sourcing.

Significant Preliminary cash for tooling and products Some processes, like stamping and roll forming, have to have customized tooling and equipment being produced to operate the process. These personalized resources can in some cases be quite expensive and only lucrative when producing plenty of sections.

As shown from the figure below, This is a simplified illustration of a posh sheet metal bending part. The bending sequence requires first bending the higher aspect after which you can bending the proper facet.

Asphalt shingles are the most vital contributors to our developing landfill issue. In distinction, metal roofing panels seldom end up in landfills. When metal panels finally demand replacement, These are one hundred% recyclable.

Sometimes the procedure generally is a progressive stamping system wherever you can find several stamping stations that steadily cut or variety the portion more and additional until the ultimate piece is developed.

Distinctive resources have special properties that make them well suited for distinct purposes, making it possible for sheet metal to be a versatile and greatly employed product in many industries.

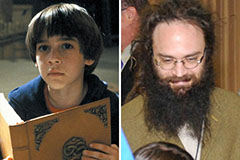

Barret Oliver Then & Now!

Barret Oliver Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Bug Hall Then & Now!

Bug Hall Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!